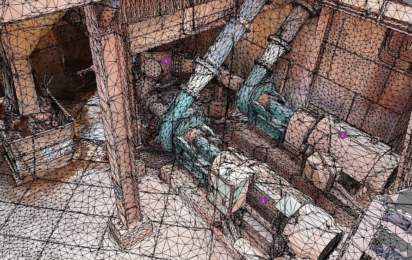

Petrography is one of the most effective methods used to evaluate building materials. Unlike other techniques, petrographic examination of hardened concrete can determine the root cause of deterioration and identify risk factors that would impact durability of the material.

By combining our in-house petrography capabilities with informed remedial and durability engineering solutions, we can provide a detailed insight into the health of your structure. This can aid in the development of targeted remediation strategies, as well as mix design verification at the time of construction.

Applications include:

Concrete

Concrete petrography plays a critical role in durability assessments of existing structures. Our experienced petrographers can determine the constituents of the cement paste, classify the aggregate/sand type, map crack/ microcrack patterns, identify secondary deposits and more. Through this process, we can ascertain which deterioration mechanisms have occurred, are currently in progress or are likely to initiate. These include, but are not limited to:

- Alkali-silica reaction (ASR)

- Delayed ettringite formation

- Sulfate attack

- Acid attack

- Soft water attack

Heritage

When matching historic mortars and renders, knowing the composition of the original materials is paramount to creating an ideal match. Duratec’s petrographic team can determine the aggregate mineralogy and cement constituents of the sample, as well as the air content of the mortar. From the petrographic and wet chemistry data, the percentage of portland cement, hydrated lime and sand in the existing mortar is calculated, aiding in the mix design for remedial mortars and renders.

Aggregate

Understanding the potential for particular aggregates to undergo alkali-silica reaction (ASR), or have undesirable constituents, is crucial when determining suitability for use.

Aggregate petrography is used to analyse both coarse and fine aggregate to classify the rock/mineral types present and identify these deleterious constituents. The results of the analysis break down the weighted percentages of the rock and existing minerals in the sample, and these percentages can be compared to specifications to determine if the sample is suitable for use.

The MEnD Laboratory offers NATA Accredited aggregate petrography in accordance with ASTM C295 and AS 1141.26.

Other materials

Building material without standard testing methods can still be evaluated by petrography to determine its condition and properties. For example, bricks are tested to determine causes of cracking/spalling or degree of firing. Grouts can be looked at to determine their constituents and degree of hydration. Our optical microscopy facilities can also be used for forensic investigations of coatings, metals and ceramics.