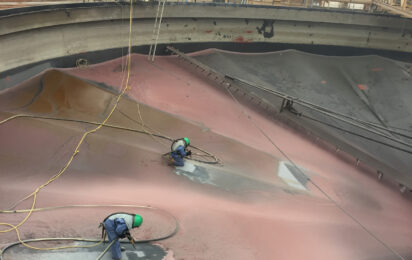

Duratec was engaged by Aqwest to perform grouting and joint repair works to a 79 million litre water tank as part of their Tech Reservoir Refurbishment Stage 3.

Details

The existing joint sealing system had failed and was causing water leaks.

The grouting works included:

- Grouting beneath roof support columns.

- Filing voids and soft/loose zones underneath the floor of the reservoir.

- Reinforcing soil materials underneath the reservoir floor to form a pattern of grout columns.

- Providing watertight repairs to core holes drilled for grouting and investigation purposes.

The joint repairs included:

- Surface preparation and minor remediation of concrete in the vicinity of the construction joints.Installation of steel reinforcement bars.

- Grouting of joints.

- Installation of a surface sealing system.

- Installation of batten system.

Design and construction of a safety system:

As the majority of the works took place on the incline of the reservoir batter, Duratec provided a custom-designed skating platform designed to move up and down the batters on winches.

Highlights

- Working in the restricted environment of a tank.

- By the completion of the project 1,200 metres of Combiflex, 10,000 litres of microfine grout injection and 89,000 of GP grout injection had been installed.

Capabilities

- Precision Grouting

- Joint Sealing