In restoring Canberra’s Commonwealth Heritage-listed National Carillon, Duratec’s local team was able to contribute to the preservation of both the historical and cultural identity of the nation’s capital.

Heritage restoration – why does it matter?

Heritage structures are physical links to the past, embodying architecture, craftsmanship and stories from previous generations. Restoring them not only safeguards our cultural assets but also enhances a community’s sense of pride. It also benefits the environment as it reduces the demand for new materials and construction, thus minimising the carbon footprint.

A bit of background

Located on Queen Elizabeth II Island, Lake Burley Griffin, the National Carillon was a gift from the British government to commemorate Canberra’s 50th anniversary. Constructed in 1970, the tower is 50 metres tall and comprises three triangular reinforced concrete shafts – each clad with pre-cast ferro-cement panels – which form nine facades in total. It also contains 57 bells, each weighing between seven kilograms and six tonnes.

What is a carillon?

A carillon is a set of bells, usually hung in a tower, played either by keys and pedals or mechanically. A minimum of 23 bells are required to be considered a carillon, however, standard-sized instruments have about 50; the world’s largest carillon has 77 bells.

Making over an icon

After more than 50 years of service, parts of the tower’s facade had deteriorated. The structure underwent a thorough investigation, which resulted in remediation recommendations.

On the back of a detailed construction management plan and tailored methodology, Duratec was awarded the major works package. The project began in October 2023 and was completed in August 2024.

Duratec’s local ACT capabilities

With a local Canberra-based workforce, Duratec was able to mobilise on site quickly and efficiently. Its team of specialist applicators has significant experience in concrete repairs and remediation, which not only enhances the operational success of a project but also contributes to optimal safety, quality and efficiency.

The task(s) ahead

The National Capital Authority, which manages and maintains the National Carillon, engaged Duratec to undertake the following works:

- Petrographic analysis of existing heritage render

- Design of heritage repair render

- Specialist facade cleaning

- Inspection of structure and documentation of defects

- Repairs to spalling and cracking (around 500 defects approved for repair)

- Breakout of existing render and panels

- Installation of fixings to reinforce lateral support to ferrocement panels

- Installation of reinforcement and pinning

- Replacement of all external panel joint sealants

- Removal of cementitious negative membrane and render repairs to internal stair shaft

- Replacement of roof drainage system and horizontal joints on roof level

- Application of waterproofing membrane to exposed ledges

- Application of protective coating to external panels

- Installation of bird deterrents to external window sills

- Replacement and reglazing of windows

Matching materials like-for-like

Materials testing

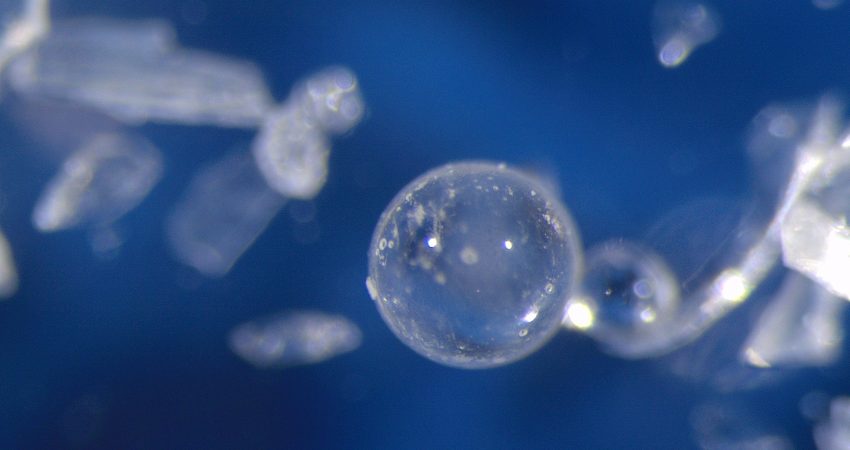

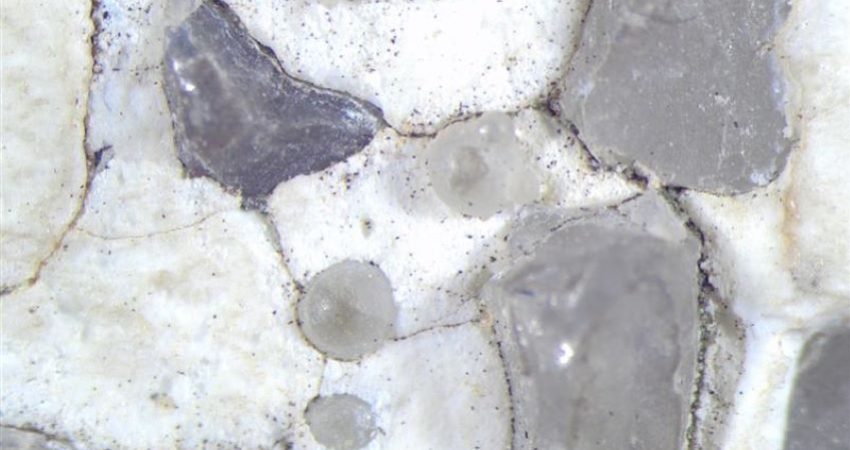

Before works commenced, Duratec’s technical services arm, MEnD, took samples of the building’s existing aggregate and render, and carried out petrographic testing to examine their contents. This was to enable the team to best match the materials and replicate the structure’s heritage finish.

The lab results are in

Following analysis of the materials in MEnD’s laboratory, the aggregate was found to contain white quartz, glass beads and crushed glass. The render consisted mainly of white cement and alite. The presence of glass in the original aggregate mix raised concerns about durability as glass can cause an alkali silica reaction, which can lead to cracking. The recommendation was to not use glass in the aggregate mix.

Trials (and tribulations) of designing a heritage render

Producing a finish that imitated the colour and texture of the existing surface was paramount. The team trialled more than 60 aggregate mixes to create a like-for-like finish, i.e. a render that looked as close as possible to the existing. The development of the render was supervised by heritage consultant Eric Martin.

Inspecting the structure

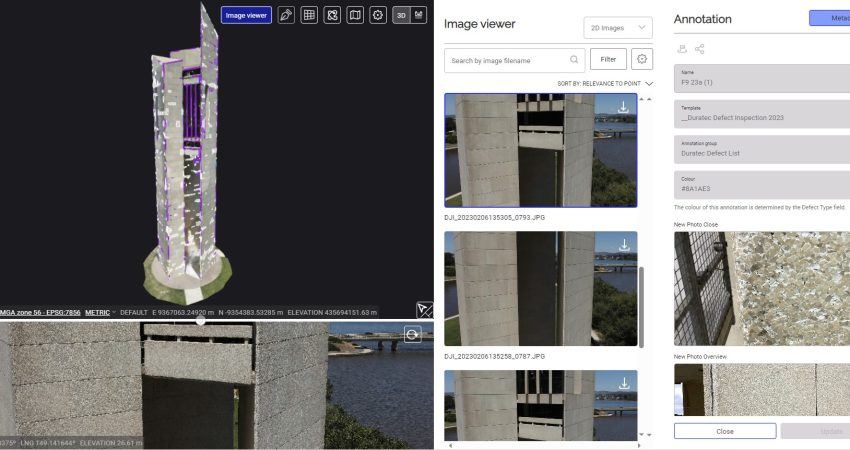

Working with the 3D model

While a 3D model of the structure already existed, its visual quality was not optimal. The captured imagery consisted of just 1,100 images, whereas MEnD’s models are usually generated from 8,000 to 10,000 images, giving them a resolution of less than one centimetre. The team, therefore, pivoted and undertook a visual inspection, capturing data more to use in conjunction with the

3D model.

Visual inspection

The visual inspection involved the use of mast climbers, scissor lifts and other access methods, which allowed the engineers to move up and down the facades. As defects were identified, they were recorded in the digital 3D model using iPads or laptops.

As well as photos, the model was populated with measurements, comments, priorities and other data. It then became the central point of truth for the project.

Digital defect management

This instant digital data entry with spatial context provided immediate visibility to those off-site and facilitated seamless remote collaboration. As the 3D model was populated with data, engineers and project managers across the country could view the updates in real-time.

Comprehensive PDF reports were generated for each facade, enabling stakeholders to preview defects before site visits. This assisted in reducing time, resources and costs. It also reduced project risks by improving data accuracy, enhancing communication and enabling faster decision-making.

Quality control was bolstered through comprehensive documentation and the ability to track the status of each defect from identification to repair.

The main works

Repair methodology

Prior to the commencement of works, Duratec prepared a detailed work method statement (WMS), which included the following actions:

- Preparation of substrate and steel reinforcement bars

- Break out of concrete

- Removal of corroded spreader plates

- Replacement of bars

- Installation of pins where spreader plates are removed

- Repair of internal cracks

- Application of primer to bars

- Application of repair mortar

- Application of heritage mortar

- Sealing of mortar

Challenges faced (and overcome)

Reaching the top

Given that the Carillon is 50 metres tall, it was important to select the correct access methodology. Options included scaffolding, mast climbers or a hybrid solution. In the end, a hybrid model was chosen. Mast climbers were used up to the lower roof level, while scaffolding was constructed above this level in order to provide access to all areas.

Four mast climbers, in total, were used across the nine facades. In the latter stages of the project, other access methods, including scissor lifts and rope access, were used to expedite the works. Mobile scaffolding was used initially for the internal facades until the mast climbers could be moved to complete the work.

Crossing the bridge

Queen Elizabeth II Island is connected to the mainland by the John Gordon Footbridge which has a weight limit of six tonnes. This meant the crew could not transport machinery that was too heavy and equipment had to be delivered in multiple loads.

In devising the construction methodology, Duratec took the bridge’s weight limit into account, selecting machinery and managing logistics accordingly.

Applying the heritage render

Once the heritage render mix had been trialled, deemed the most like-for-like and approved for use, detailed quality measures were put in place to ensure work methods were followed and a high-quality finish would be achieved. Again, this process was supervised by heritage consultant Eric Martin.

Working with the weather

Canberra’s weather posed several challenges when it came to access. The mast climbers could not be used in windy conditions – as soon as the wind speed reached 45 kilometres per hour, workers were required to stop work and descend.

To monitor conditions and ensure the safety of workers, Duratec installed weather stations on each machine.

Cold temperatures also elicited some out-of-the-box thinking regarding the curing of the render. Duratec worked with material manufacturers, trialled various products and landed on the best solution for the job.

Preserving the environment

Environmental conservation was a key consideration for both Duratec and the client, right from the beginning of the project. The main areas of concern were:

- Aquatic environment (Lake Burley Griffin) protection

- Waste management

- Tree protection

Duratec implemented a number of measures to address these concerns, including:

- Management of groundwater to prevent runoff or materials from entering the lake

- Minimisation of waste and maximisation of recycling

- Operation of vehicles and machinery in a manner that prevents damage to trees and vegetation

Recipe for success

The successful delivery of the National Carillon project showcases Duratec’s ability to combine digital technologies with innovative remediation solutions to overcome the often complex challenges involved in heritage restoration works. It also demonstrates that the presence of a local Duratec team is of great benefit when it comes to streamlining processes, improving efficiency, encouraging collaboration, and maximising time and resource savings.

Fast facts

- The National Carillon was designed by WA architects Cameron, Chisholm & Nicol

- Queen Elizabeth II officially opened the National Carillon on 26 April 1970

- The tower’s three triangular shafts align with one of the three sides of a central equilateral triangle

- Each shaft serves a different function – the highest has a passenger lift; the next, a steel staircase; and the lowest houses a service shaft

- The tower’s first floor is about halfway up the tower and contains the chamber for the clavier that operates the bells, and space for musicians and the carillonist

- Above this is the bell chamber and 36m above ground level, is the ‘Chimes’ viewing area