Duratec collaborated with design consultants and contractors to find practical ways to bring this important cultural structure to life.

Construction of the Northern Territory Art Gallery is due to commence later this year, however, detailed design and planning has been in the works for some time. Duratec was pleased to accompany the project design team through an early contractor involvement phase – a model which provides clients with a raft of benefits and better project outcomes.

How it began

In late 2022, Sitzler was engaged by the Department of Infrastructure, Planning and Logistics (DIPL) to construct the Northern Territory Art Gallery – a four-level building in Darwin’s State Square. The building is to form a major part of the city’s revitalisation, bringing together art and architecture, while imbuing a distinct sense of place.

A design concept had already been developed by local Darwin practice Ashford Lamaya Architects, Clare Design and Hully Liveris Design Company. The structure was to consist of post-tensioned slabs, precast and blockwork walling, and aluminium sheeting with decorative slats. Central to the design concept was anodised aluminium cladding in the bespoke colour of ‘tabasco’ – a tone that resembles the landscapes of the Top End. This cultural facility was going to make a striking aesthetic statement.

Engagement and collaboration

Once the initial design concept had been presented, Sitzler reached out to Duratec to look at the design from a constructibility perspective. Duratec collaborated with design consultant Inhabit to provide input into the best way to bring the design to life. The aim was to come up with practical methods that would optimise project outcomes, such as value-for-money, efficiency, quality and performance.

Design review

Duratec’s in-house design team got to work reviewing the design and collaborating with stakeholders on constructibility, as well as procurement, fabrication and installation of the panels. Climatic conditions were also considered, as were Indigenous interests – DIPL’s contract with Sitzler required 8.8 per cent Aboriginal employment.

In undertaking the review, Duratec’s tasks included:

- Coordination of consulting team and deliverables

- Review of drawings and documentation

- Proposal of value-add design concepts

- Analysis of constructibility and installation

- Provision of preliminary engineering input

- High-level drafting of final concept design

Proposed design options

A workshop was held to evaluate the proposed design options, which were split into three pillars – access, fabrication and design. The team analysed each pillar’s two construction methodology options to determine which would provide the best possible outcomes, including long-term performance.

1. Access methodology: scaffold vs EWP

Scaffolding was the preferred access method to not only facilitate safe installation of the precast walls but also provide access to other trades.

Why scaffolding?

- Works can occur on multiple levels concurrently

- Scaffold set-up costs for other works can be shared with facade installation scope

- EWP poses risks on unlevel ground in wet season

- Scaffold provides dropped object protection

2. Fabrication methodology: cassette panels vs modular units

The chosen access method, i.e. scaffolding, informed the fabrication methodology. It was determined that cassette panels would be best.

Why cassette panels?

- Large, modular units would necessitate a tower or crane to lift them into position; this would require solid ground, which is limited in the wet season

- Design intent required multiple module types which could not be mass-produced

- Engineering of structure allows for slab loading

3. Design methodology: face-fixed vs cassette system

The team decided upon the adoption of a cassette system for the design methodology.

Why a cassette system?

- Removes face fixings, improving aesthetics and reducing potential for maintenance issues

- Removes one vertical band so no central fixing is required; this leads to reduction in scope fixings

- Accommodates need for a vapour barrier system and weatherproofing

- Bolt connection details, rather than drilling of 10mm steel, reduce installation time

Advantages of the design option

The chosen methodologies informed the design concept, which offers many advantages as it:

- Maintains architectural intent

- Reduces amount of site fixing

- Requires fewer fixed components/site materials, i.e.

- Eliminates 30 per cent of top hats, using them instead as stiffeners in panels

- Uses bolt connection details to support members in lieu of drilling 10mm steel

- Allows for off-site assembly of panels

- Cassette panels enable removal of visible fixings

- Stiffening of panels for cyclonic impact is incorporated into fabrication process

- Accommodates building tolerances, movement and adjustment during site installation

Challenges overcome

The project team faced a number of challenges but by working collaboratively, they were able to come up with tailored solutions to solve these issues.

Material: anodised aluminium in ‘tabasco’

As mentioned, the initial design concept called for external aluminium sheeting but not just any sheeting – it had to be anodised aluminium in the bespoke colour of ‘tabasco’. This material is produced by only one supplier in Australia – Sapphire Aluminium in Somersby, New South Wales.

Procurement – local presence

Duratec was able to procure the product swiftly and efficiently, thanks to the business’ nationwide footprint and local presence. Duratec has three branches in New South Wales alone.

Experience building in cyclonic conditions

With a local branch in Darwin, Duratec has vast experience in the remediation and construction of buildings in tropical climates. As a result, the design was customised to suit cyclonic conditions.

Fabrication and pre-assembly

With its knowledge of and experience working with anodised aluminium, Duratec has a strong understanding of the material’s sensitivities. The team knows how to handle the material and is familiar with its fabrication and pre-assembly.

A prototype is born

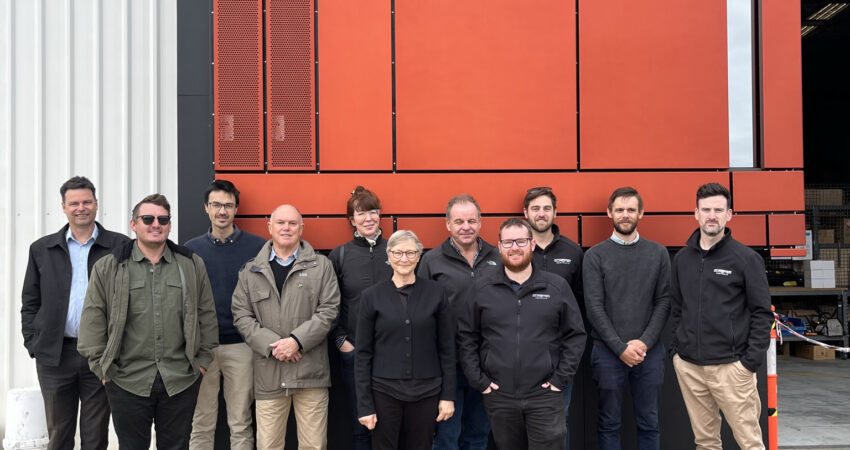

In order to provide the client and other stakeholders with tangible evidence of Duratec’s capabilities, the team constructed a prototype – a tabasco-coloured, anodised aluminium wall. Stakeholders involved in the design process travelled to inspect this visual mock-up (VMU) and included Clare Design; NT government agencies DIPL and the Department of Territory Families, Housing and Communities; Sitzler; and Inhabit. The VMU allowed all to visualise how the art gallery’s facade once construction is complete.

The next steps

In mid-December 2023, Duratec was thrilled to be awarded the main works package and will work alongside Sitzler to bring the design team’s vision to life. Once completed, the building will comprise:

- Basement – plant, loading areas and storage

- Ground – art galleries and retail space

- Level 1 – function areas and storage

- Level 2 – art galleries and storage